Simplex Motion Tool

The SimplexMotionTool software runs on a PC computer in the Windows environment and allows the user to configure and test the Simplex Motion motor units.

The software communicates with the motor unit using the USB or RS485 communication interface.

REGISTERS

The functionality of the motor unit is entirely controlled by registers that can be read and written. The Register tab allows the user to inspect and change these registers. The registers are updated in real time and form the parameters and settings of the motor system. The current register values can also be saved to the memory to be loaded at the next startup.

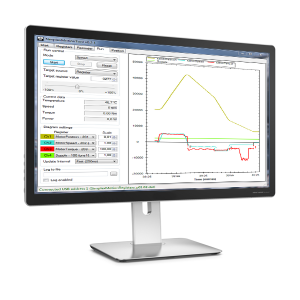

RECORDER

To facilitate performance validation and optimization it is necessary to be able to measure parameters in the motor device. To accomplish this there is a recorder feature within the Simplex Motion unit. The Recorder tab allows direct access to this recorder feature. Up to 4 channels can be recorded simultaneously, and can be triggered from different events.

The following screenshot shows a recording of some registers when the motor changes direction from positive to negative direction of rotation. In this case it takes about 0.15s to change the speed from +2300rpm to -2300rpm.

RUN

The Run tab can be used to make it simple to quickly test the motor. Run the motor in speed, position or torque mode using the buttons. A few common motor data values are shown, and other can be selected for inspection in the rolling graph. These data can also be logged to a file. Graphing and logging is running even if the motor is controlled from another interface, allowing this to be a convenient way of debugging.

POSITION

The Position tab is used to tune the relevant parameters and inspect performance for point to point moves.

Typical use for the Simplex Motion devices is in position control with rapid transfers from one position to another. To accomplish this with high performance and a minimum of mechanical vibrations it is important to use ramping where the acceleration and maximum speed are controlled.

To further improve performance when dealing with high inertia loads it is common to use feed forward control in addition to the PID feedback regulator.